IT IS ECONOMICAL TO INSULATE EVERYTHING WITH

TEMPERATURE EXCEEDING 100 °C !

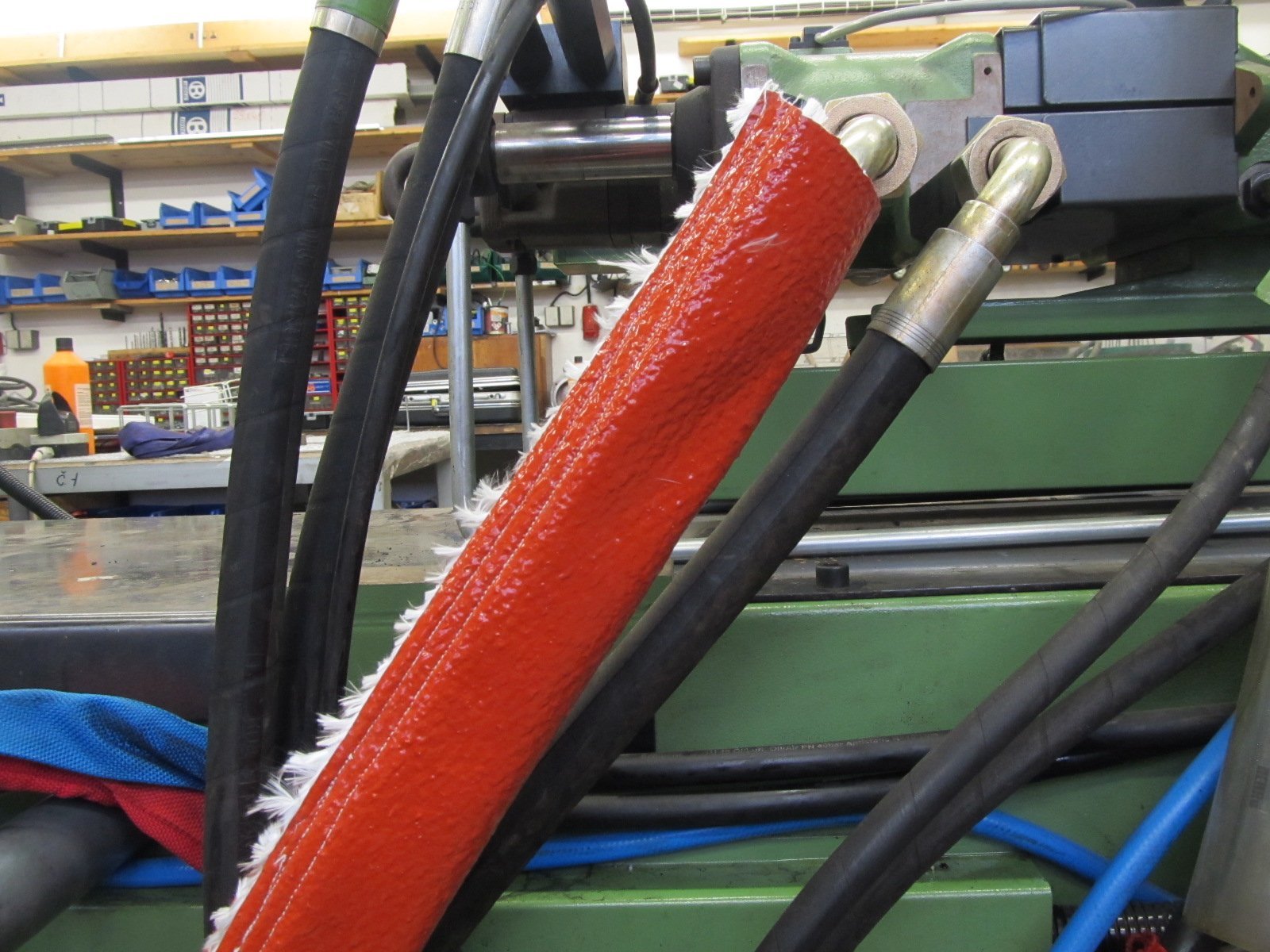

The operating parts of machines (barrels, cylinders) are tempered during manufacturing of plastic products to the temperature necessary for processing of the specific material. Since this generally relates to continuous operations, the electricity expenses for tempering of the machine comprise a significant part of production financial costs. To decrease the electricity consumption costs on these machines, we offer installation of thermal insulation covers.